![[Image] Brake System](../../../../images/Products/OEMproducts/New/Steering/EPSroadmap.png)

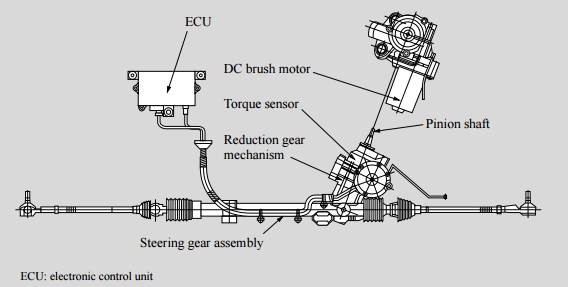

Electronically controlled steering was initially limited to speed sensitive power steering systems. There are two types of power steering systems: electric power steering systems and hydraulic power steering systems. Currently hydraulic power steering systems are widely used, but electric power steering systems are rapidly coming into use, primarily in small passenger vehicles. EPS (electric power steering system) designed for small passenger vehicles that are currently mass produced. It conveys the motor torque to the steering gear from the pinion shaft through the reduction gear mechanism.

The pinion assist type electric power steering systems Hitachi Automotive Systems Americas, Inc. is currently mass-producing consist of:

The electronic control unit controls speed sensitive power steering systems by processing signals indicating the vehicle speed and the rotation of the engine. In addition, the torque limiter is positioned between the plastic gear in the reduction gear mechanism and the pinion shaft, and this protects the plastic gear from road surface pressure.

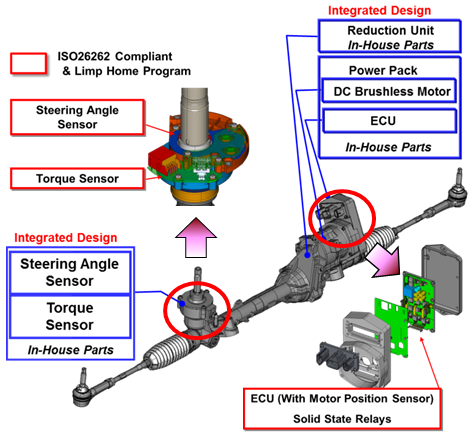

Hitachi Automotive Systems Americas, Inc. Belt Drive Electric Power Steering System with enhanced steering feel and ISO 26262 ASIL-D compliant design.

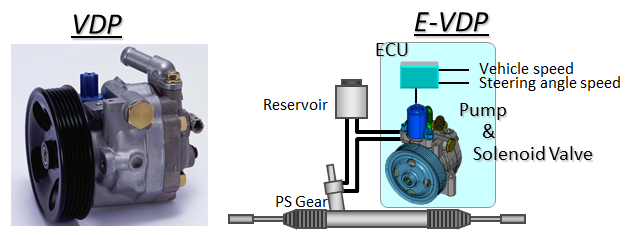

VDP and e-VDP for power steering to realize fuel economy improvement .This pump type has been developed to assist the automotive industry in reducing the fuel consumption and CO2 emissions particularly of upper mid-size and luxury cars to Large Trucks. Variable Displacement Pump makes a significant contribution to reducing the energy consumption of hydraulic steering systems and is characterized by a variable flow rate. The adjustable curve ring enables the control of the geometric flow rate depending on the speed. So the pump supplies always based on the required characteristic curve of the supply rate.

VDP is an oil pump for power steering used to achieve energy savings by

eliminating a pump’s excessive operation as well as reducing driving torque by variably-controlling the displacement automatically corresponding to the pump speed.

e-VDP achieves even greater energy saving by electronically-controlling the discharge flow rate in accordance with certain vehicle parameters (vehicle speed, steering angle speed, etc.) in order to improve fuel economy

and reduce CO2 emission.