Hitachi Automotive Systems Americas, Inc. is engaged in thorough processes from development to production of various pistons meeting customer needs for higher functionality and lower costs. Hitachi Automotive Systems Americas, Inc. has succeeded in adopting higher compression ratios to improve efficiency through better anti-knock performance using pistons and direct injection of gasoline (DIG) engines, and is working on the development of engine downsizing systems based on direct injection of gasoline (DIG) engines and the associated high boosting technology. Proprietary features include low friction, reduced HC reduction of emission, and light weight resulting from the unique skirt structure. Hitachi Automotive Systems Americas, Inc.'s Pistons are more responcible for improveing Anti-Knock Performance, Reduction of Particulate number/particulate matter[PN/PM] (DI) and for Engine High Efficiency.Pistons are consider as a part of High Efficiency Internal Combustion Engine System : ICE System.

Increase the engine compression ratio for fuel consumption improvement by decreasing engine piston temperature.

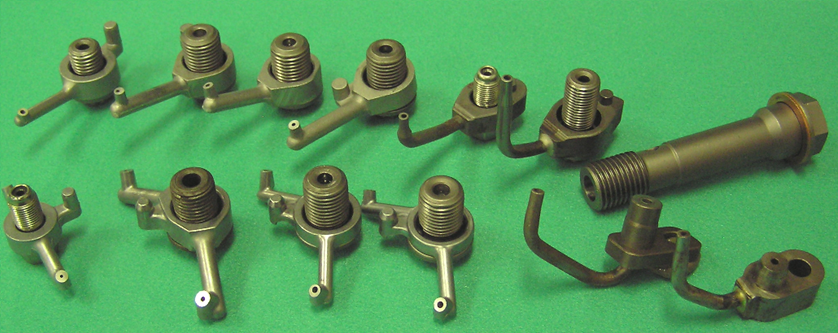

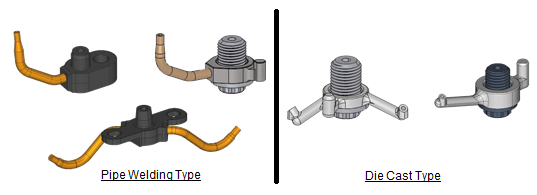

Piston cooling system are used to improve anti-knock performance. Piston cooling for better anti-knock performance is achieved by incorporating cooling channels into the pistons and using a variable-capacity oil pump to control cooling based on operating conditions.This Cooling Gallery Piston with ring carrier is acting main role in thermal management in Engine Powertrain System.