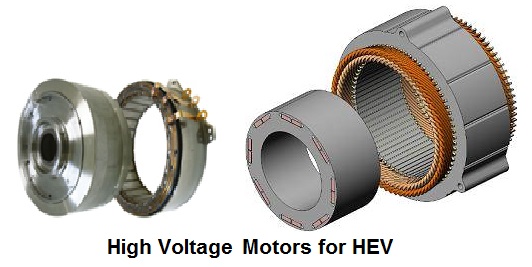

With vehicle fuel economy and exhaust gas emission regulations being strengthened in response to global environmental problems, attention has focused on the use of electric drive systems in vehicles. Hitachi Automotive Systems Americas, Inc. has had a long involvement in the development of electric motors with high output ratio and has adopted the IPM (interior permanent magnet) synchronous motor for use as an electric drive motor for vehicles. IPM synchronous motors combine small size, light weight, high output and high efficiency. Although HEVs combine an electric motor and gasoline engine, the distance that these vehicles are able to travel in EV mode where they are powered by the electric motor only is increasing.

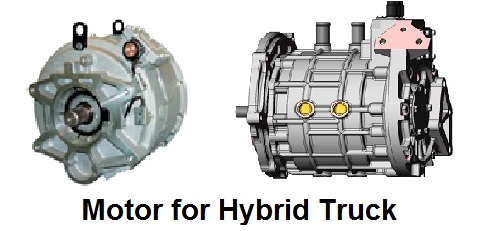

Hitachi Automotive Systems Americas, Inc. is in production on a "hybrid" vehicle. Shown above is the electric traction motor housing between the internal combustion engine and the gear. The traction motor can provide main or supplemental power to the vehicle.

This is the

auxiliary electric motor, which provides the starting ability in internal

combustion engines, as well as providing electrical power generation to charge

batteries.

This is the electric motor that drives the CVT transmission oil pump providing power to control the transmission ratio (drive).

Hitachi Automotive Systems Americas, Inc. is in

production of and provides complete system compatibility for EV and PHEV

applications. The other motor and inverter is used in a small Nissan full

electric vehicle (Hyper-Mini).